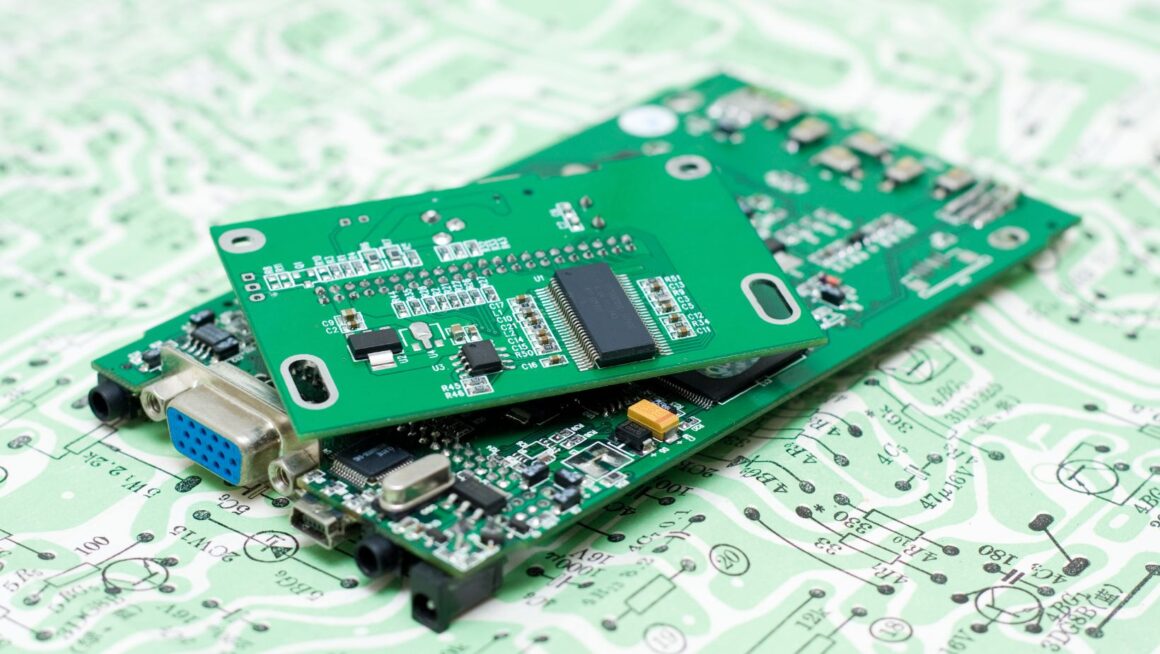

Printed Circuit Boards (PCBs) are the backbone of modern electronics, playing a crucial role in various industries. Understanding the different types of PCBs and their specific applications can help businesses choose the right solution for their projects. For instance, OurPCB pcb maker provides a range of high-quality PCBs suitable for various needs, from high-frequency boards used in telecommunications to durable options for automotive electronics. Each type offers unique benefits that can significantly impact performance and reliability.

Printed Circuit Boards (PCBs) come in different types based on their construction and intended uses. Each type offers unique attributes suited for specific applications.

- Single-Sided PCBs:

- Construction: These PCBs consist of a single conductive copper layer above the substrate.

- Applications: Commonly found in basic and low-cost electronic devices, such as calculators, power supplies, LED lighting boards, FM radios, and timing circuits.

- Double-Sided PCBs:

- Construction: This type features conductive layers on both the top and bottom of the board.

- Applications: Utilized in complex devices like cell phones, amplifiers, power monitoring systems, test equipment, HVAC systems, and uninterruptible power supplies (UPS).

- Multi-Layer PCBs:

- Construction: Multi-layer PCBs contain at least three conductive layers sandwiched between insulating materials.

- Applications: Found in sophisticated electronics such as computers, laptops, mobile phones, tablets, medical devices, GPS trackers, and advanced circuits.

These PCB types demonstrate versatile applications across various industries, ensuring functionality and reliability in electronic devices.

Types of PCBs

Printed Circuit Boards (PCBs) come in several types, each catering to different application needs. Understanding these types is crucial for selecting the right PCB for a specific device or industry.

Single-Sided PCBs

Single-sided PCBs feature a single conductive copper layer above the substrate. Components mount on one side, while the etched circuit remains on the opposite side. This design offers simplicity and cost-effectiveness.

Common applications include basic electronics such as calculators, power supplies, LED lighting boards, FM radios, and timing circuits.

Double-Sided PCBs

Double-sided PCBs consist of two copper layers on the top and bottom. Holes in the circuit board facilitate connections between the two sides. This configuration allows for reduced sizing, lower overall costs, and increased circuit density. Typical uses include devices that require more components and complexity, such as amplifiers and industrial controllers.

Multi-Layer PCBs

Multi-layer PCBs consist of three or more conductive layers separated by insulation layers. This construction supports intricate designs in compact spaces. Multi-layer PCBs cater to advanced applications, including computers, medical equipment, and telecommunications devices that demand high performance. Their ability to accommodate extensive circuitry contributes to reliability and efficiency.

Rigid PCBs

Rigid PCBs combine solid substrates with fixed shapes. Their sturdy construction supports electronic components while offering durability. Rigid PCBs are ideal for applications needing stability and structural integrity, such as automotive electronics and consumer appliances. The robust design enhances longevity and performance in various conditions.

Flexible PCBs

Flexible PCBs utilize thin, flexible materials, allowing them to bend and conform to specific shapes. Their design enhances versatility and integrates into compact devices. These PCBs find applications in wearable electronics, smartphones, and medical devices where space is limited. The flexibility contributes to overall product design and functionality.

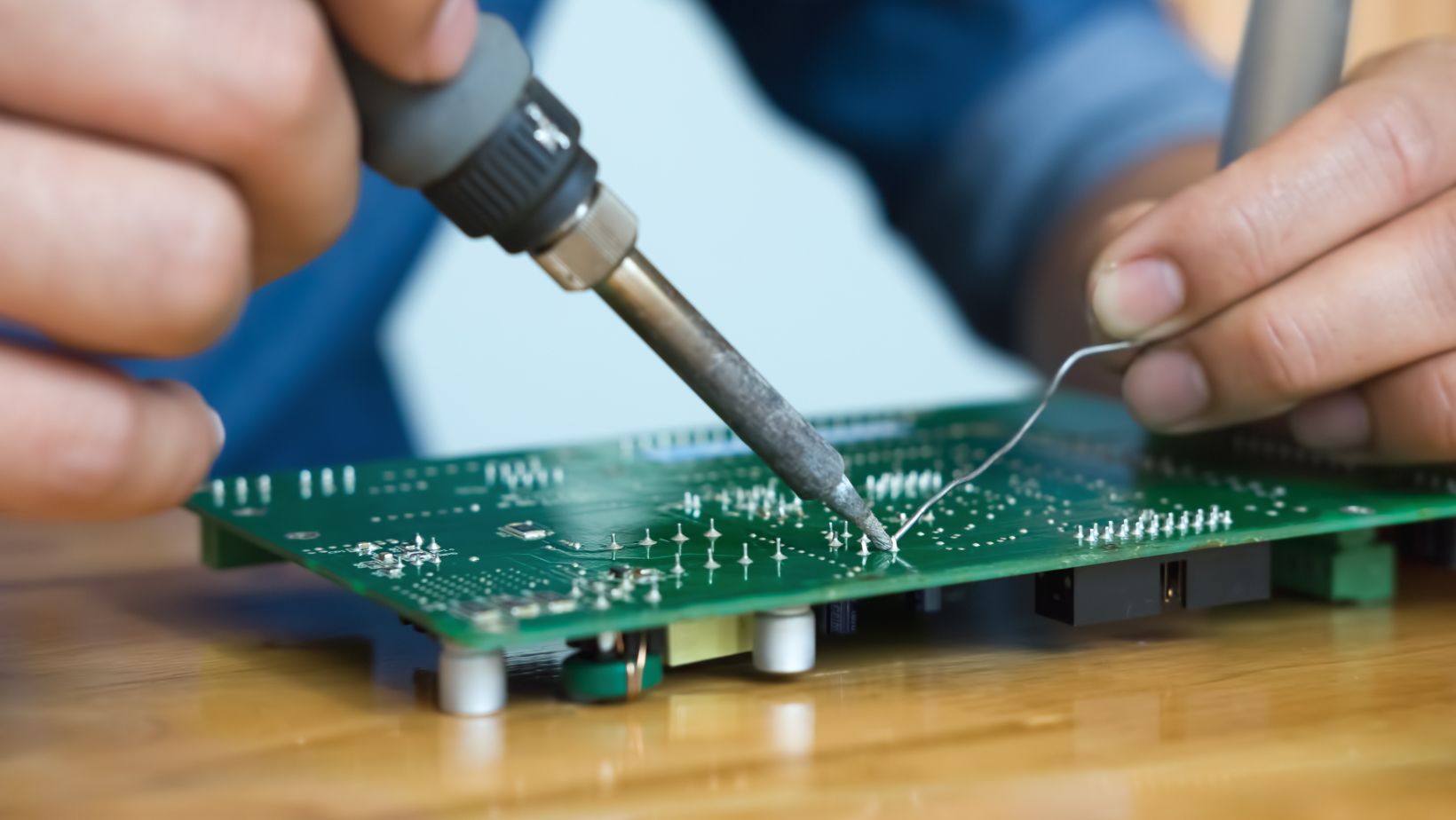

Applications of PCBs

PCBs serve crucial roles across multiple industries due to their versatility and functionality. Below are key applications where PCBs make a significant impact.

Consumer Electronics

PCBs play an essential role in consumer electronics. They are integrated into devices such as smartphones, televisions, and home appliances. The use of single-sided and double-sided boards accommodates low and medium-density designs, making them suitable for electronic toys and personal gadgets. These PCBs enable efficient performance and space-saving designs, ensuring reliable operation in high-demand environments.

Automotive Industry

PCBs are vital in the automotive industry, supporting functions ranging from infotainment systems to advanced driver-assistance systems (ADAS). Double-sided and multi-layer PCBs provide the necesary durability and heat resistance required for automotive electronics.

They ensure reliable communication between electronic components, contributing to vehicle safety and enhanced performance.

Medical Devices

In medical devices, high-precision PCBs are critical for instrumentation and diagnostic equipment. Multi-layer PCBs facilitate compact design while maintaining functionality and reliability. Their usage in items such as monitors, imaging devices, and diagnostic tools underscores the importance of quality and precision in this industry, where mistakes can lead to severe consequences.

Aerospace and Defense

PCBs in aerospace and defense applications must withstand extreme conditions and operate reliably. They utilize high-frequency and specialty PCBs designed for harsh environments. These boards ensure effective communication, navigation, and control systems in aircraft and defense systems, making them indispensable for safety and mission success in these critical fields.

Conclusion

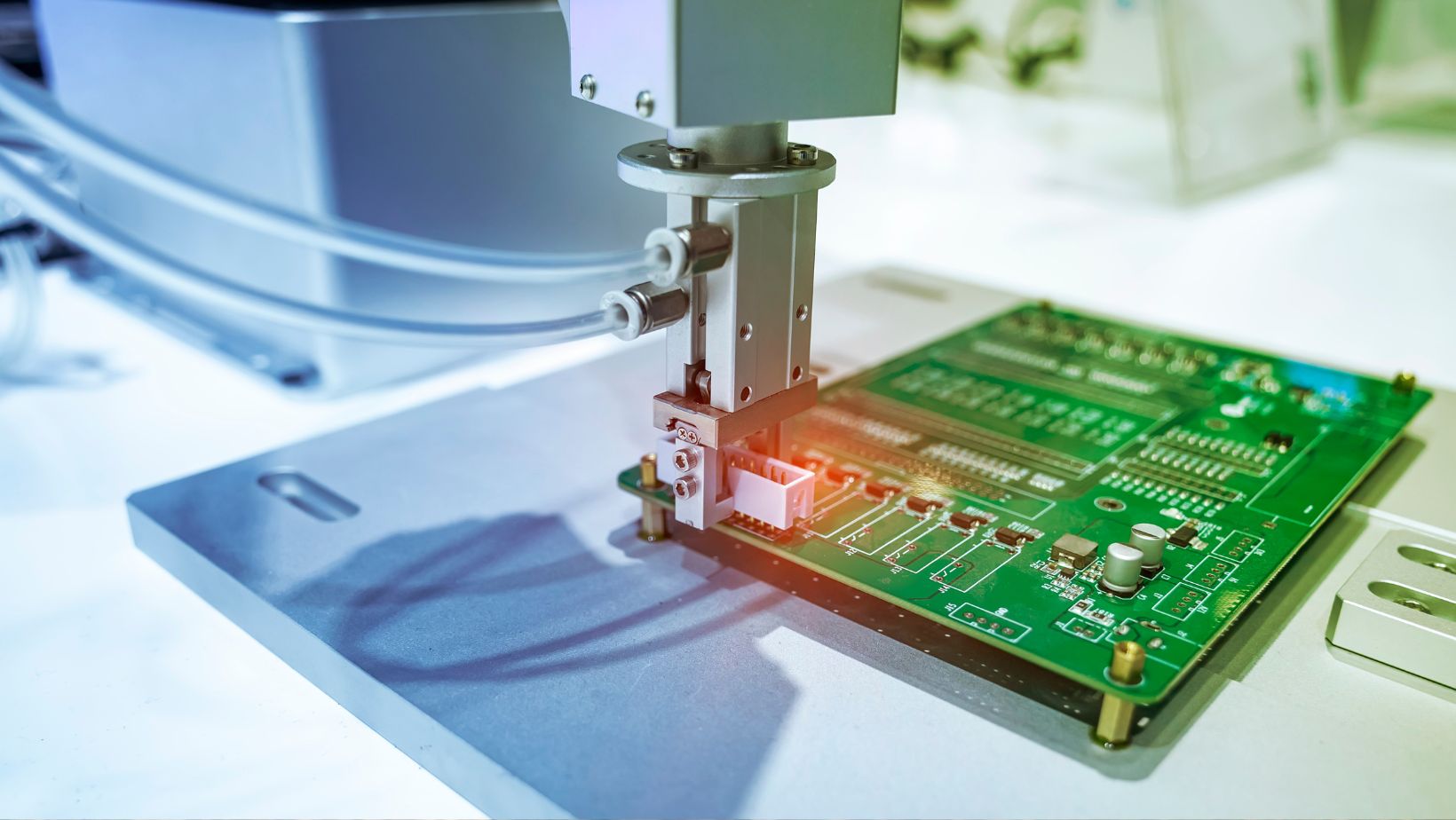

Understanding the different types of PCBs and their applications is crucial for anyone involved in electronics. Each type serves a unique purpose and meets specific industry needs. By selecting the right PCB, businesses can improve product performance and reliability while ensuring compliance with industry standards. As technology continues to evolve, so will the innovations in PCB design and manufacturing. Staying informed about these advancements will empower companies to make better choices in their electronic projects.